WOOD. NAT. PLA+ 1.75mm 1KG ECO

WOOD. NAT. PLA+ 1.75mm 1KG ECO

3D Printer Filament

PLA+ Wood 1.75mm Natural 1KG ECO

Weight: 1kg

Colour: Natural Wood

Material: PLA+

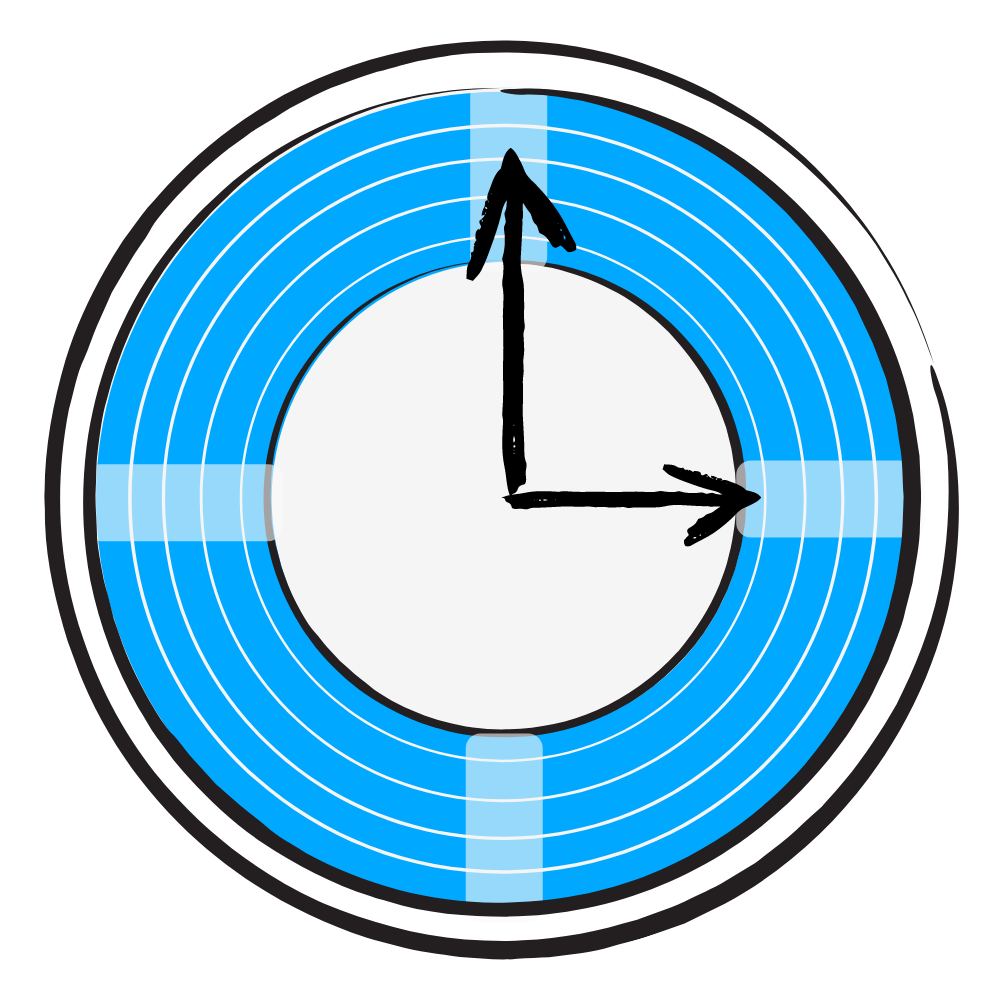

Nozzle Temperature: 200°C - 210°C*

Bed Temperature: 0°C - 60°C

Diameter: 1.75mm ± 0.03mm

Hardware Requirements

| Heated Bed: Optional Enclosure: No | Hardened Nozzles: Required |

Adhesion Aids:

Not Required |

Part Cooling Fan: Yes |

PLA Wood is a composite material blend of PLA and real wood fibres which results in biodegradable 3D parts with the texture and feel of real wood. The resulting parts can be sanded and stained like real wood, allowing for complex, single-peice geometries that look and feel like the actual thing.

Precision engineered to industry leading tolerances (±0.03mm) using advanced laser technology, our filaments make possible silky smooth prints with perfect layer adhesion resulting in stronger prints with no variations in surface quality. Our filaments are orderly and uniformly wound on each spool ensuring a jam and kink free printing experience. Made from only pure feedstock and vibrant pigments, our filaments are available in a multitude of vibrant colours and is compatible with all 1.75mm filament fed 3D printers from your favourite manufacturers like Prusa, Creality, Monoprice, FlashForge and more.

Abrasive Filament WarningIn comparison to standard 3D printing filament, this material is abrasive. When printing this material, users will find that standard brass nozzles are quickly worn out, resulting in their inner surfaces becoming wider. This will cause problems with extrusion over time. As a result, we strongly recommend printing this material using only with printers equipped with hardened steel nozzles. |

|---|

PRINTING PARAMETERS

Print Speed: 30 - 80 mm/s

Printing Temperature: 190 - 210°C

Build Bed Temperature: 0 - 50°C

Retraction Speed: 20 - 50 mm/s

Retraction Distance: 3 - 10 mm

Cooling Fan: Yes

Filament Type: PLA+ Wood

Printer Type: Cartesian/Delta

Extruder Type: Direct Drive/Bowden Tube

Layer Height: 0.1 - 0.3mm

Fill Density: 0 - 100%

Shell Thickness: >0.4mm

*Not all 3D printers are the same. This makes giving temperature advice difficult. Consider the suggested printing temperature as a starting point to be fine tuned as you experiment and print with our material. Don't be afraid to go above or below our suggested temperatures if it results in better quality prints. For more information on how to get the best our of your STANDARD PRINT CO. PLA Filament, head over to our PLA Guide and download a free copy of our PLA printing guide.

+ Why Standard Print Co.?

+ What is PLA Wood used for?

+ How do I best print PLA Wood?

+ How do I refill a Standard Print Co. ECO Spool.

+ Do you offer PLA Wood in 2.85mm diameter filament?

Need help getting the best out of your STANDARD PRINT CO. filament?

When you are in edit mode or signed in to Squarespace, you cannot see any Wiremo changes.

However, if you open a tab in Incognito mode, or in a separate browser that you are not signed in to your site with, you should be able to see your reviews.

What are the best settings for 3D printing in HIPS? Find out in our Quick Start Guide which contains the best settings AND explanations for printing in HIPS.