Recycling your ABS 3D print waste

Turning scraps into glue - How to make ABS slurry

ABS scraps can be melted down to form an “ABS slurry”

ABS slurry can be used to fuse ABS parts together forming a chemical bond

The ABS slurry can be stored in airtight containers for later use

You’ve just finished printing the largest and most complex print of your life and are about to remove it from the print bed. You start to remove the support material with the care you reserve only for handling newborn puppies, when the unthinkable happens.

You snap the print cleanly in half.

While your first instinct would probably be to reach for a tube of superglue (and let out a choice expletive...), you should probably know that makers are increasingly turning to the use of “ABS” slurries over traditional super glue. Serving the dual function of being an adhesive and filler agent, the slurry can be used to glue and plug gaps too large for gluing, all the while offering a stronger adhesive bond than traditional super glue. Better still, if the slurry is prepared in the same colour as the parts you intend to apply it to, once allowed to dry, the slurry can be sanded back, leaving an almost invisible join of ABS plastic.

We haven’t even got to the best part yet - It can be made at home from nothing more than your ABS printing scraps and a measure of acetone.

How to Make ABS Slurry

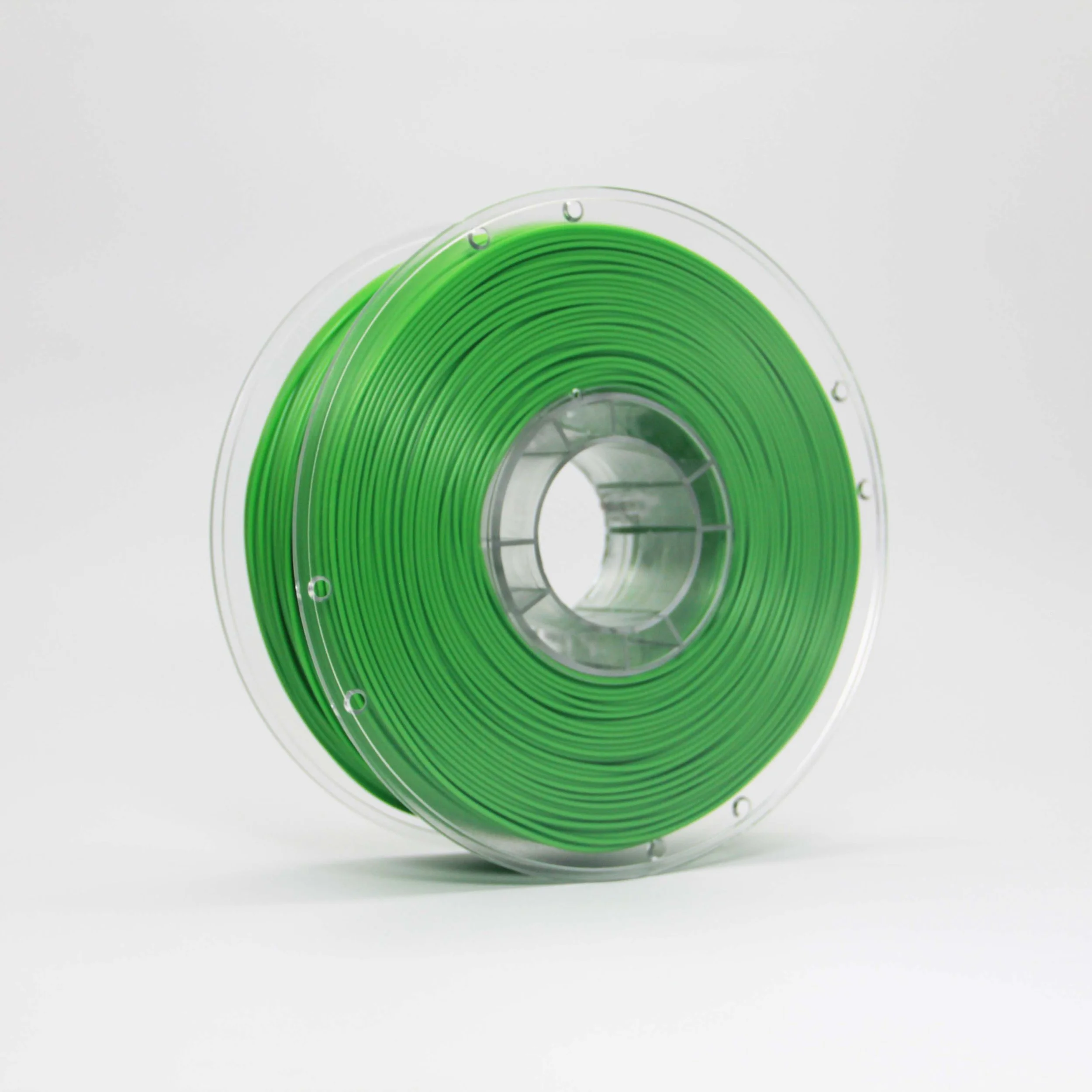

Simply prepare by mixing 1 part ground ABS filament (We used an old Prolex Coffee Grinder for added hipster cred.) to 2 parts acetone, the acetone acts to dissolve the ABS, forming a thick paste, which can then applied to your 3D prints. Left in open air, the acetone quickly evaporates, leaving behind only the solid, reformed, ABS plastic. By storing freshly made batches of the slurry in airtight containers, slurries can be prepared in a multitude of colours and stored for later use. We found empty nail polish bottles to be the best containers, but refrained from using the synthetic brush included in the cap as the acetone has a tendency to melt the fibres. Instead, we used a neutral, natural fibre brush to apply the slurry, cleaning the fibres with acetone after use.

It is also important to note that while you can use the ABS slurry to “glue” PLA parts together, the resulting bond will be significantly weaker than that of an ABS-to-ABS bond due to PLA not being soluble in acetone. Due to this fact, a “PLA slurry” cannot be produced with this technique.

The Disclaimer

While it is easy to see the benefits of using ABS slurries, it would be remiss of us to not mention its drawbacks. The first being the strength of the bond. While the slurry does provide a bond stronger than that offered by the surface adhesion of super glue, the acetone “melt zone” doesn’t permeate deep under the surface of the applicator area. As such, the weld that is created provides less shear resistance than that of 3D printed part. To combat this, design the area to be glued with an interlocking design, or design a joint that maximises the surface area that is to be glued.

Secondly, it is important to keep the slurry clear of any sources of ignition as you are effectively creating a batch of plastic “napalm” which is difficult to put out and emits toxic fumes when burnt. As such, it is important to maintain the same care in handling as you would of any other extremely flammable substance and to treat any fires as chemical fires. Most of all remember to wear appropriate safety equipment, handling with extreme caution and undertake at ones own risk.

FAQ’s